5 Ways Businesses Can Enhance Precision and Cut Production Costs

In today’s manufacturing landscape, precision is not just a benchmark but rather a necessity. Even small errors can lead to costly waste, rework, and lost time. At the same time, production teams face growing pressure to do more with less, from controlling material costs to shortening lead times.

Finding that balance between accuracy and affordability often feels like walking a tightrope. The truth is, success rarely depends on one single improvement. It’s the combination of better processes, smarter technology, and consistent monitoring that truly drives measurable results.

This article explores five actionable ways businesses can enhance precision while keeping production costs in check.

1. Strengthen Process Control and Fixturing

Precision begins long before a cutting tool or machine even starts. It starts at the process level, with how operations are standardized, materials are handled, and parts are secured.

When processes are inconsistent, even the best equipment can’t compensate. Simple variations, like a loose fixture or misaligned workpiece, can lead to tolerance issues and costly rework. That’s why refining process control is one of the smartest investments a business can make.

Here’s what helps maintain tighter control across the board:

- Standardized work instructions: Clear, repeatable steps keep quality uniform across shifts and operators.

- Smart fixturing systems: Modular or quick-change fixtures reduce setup errors and speed up transitions between jobs.

- Operator training: Well-trained teams spot potential mistakes early, preventing downtime and material waste.

When every part of production follows the same rhythm, precision stops being a goal — it becomes a habit. And that consistency builds the foundation for everything else that follows.

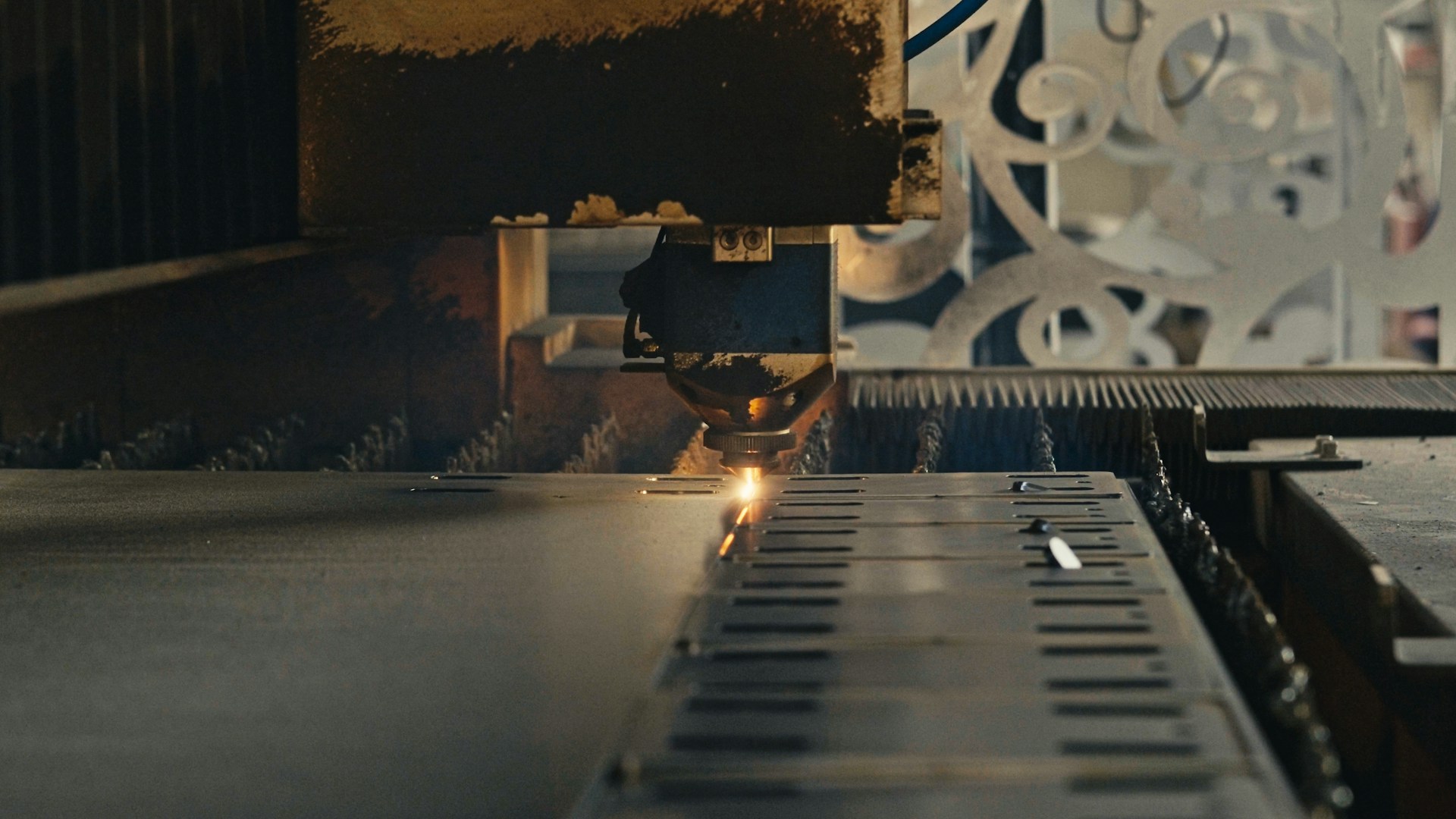

2. Upgrade to Advanced Cutting Technology

Over time, aging machinery can quietly undermine precision. Dull nozzles, worn motion drives, and outdated control systems lead to subtle variations that compound across production. The result? Uneven edges, inconsistent dimensions, and higher scrap rates. Every small deviation chips away at profitability.

Upgrading to next-generation cutting systems offers a direct path to improvement. These machines maintain precision through real-time adjustments, advanced motion control, and consistent cutting performance.

A standout example is water jet cutting machines, which combine a high-pressure stream of water with fine abrasives to cut materials cleanly and consistently. Because the process is cold, it avoids the heat-related stress that can warp metal or weaken composites.

In practice, this means:

- Cleaner cuts that meet tight tolerances without rework.

- Versatility across steel, aluminum, stone, and ceramics.

- Lower material waste and improved cost efficiency.

Innovative providers such as OMAX have advanced this method even further. Their advanced water jet cutting solutions feature intuitive software and precision monitoring tools. These allow operators to achieve unmatched accuracy with less manual intervention — a crucial advantage in competitive, high-volume industries.

3. Leverage Smart Software and Automation

Technology has moved far beyond manual calibration. Today’s production systems rely on intelligent software that bridges precision with predictive insight. Automation tools not only reduce human error but also optimize how resources are used.

Here’s the thing: automation isn’t just about speed. It’s about smarter decision-making. For example:

- CAM nesting programs help plan cuts more efficiently to reduce raw material waste.

- Predictive path optimization fine-tunes tool movement for faster cycle times.

- Real-time sensors detect variations in performance, allowing instant adjustments.

By combining automation with skilled oversight, manufacturers can maintain consistent quality while freeing teams to focus on higher-value tasks. That’s precision and productivity working hand in hand.

4. Maintain Equipment with Predictive and Preventive Care

Even the most advanced machines lose accuracy if they aren’t maintained properly. Predictive and preventive maintenance go beyond routine servicing. They’re proactive systems that safeguard precision and minimize unplanned costs.

A few smart maintenance practices include:

- Scheduled calibration checks to ensure machinery stays aligned with original specifications.

- Regular part replacement for components like nozzles, pumps, or filters before wear impacts quality.

Think of it as insurance for performance. Investing in maintenance keeps machines reliable, extends their lifespan, and helps avoid those unexpected breakdowns that can throw production off schedule.

5. Use Data-Driven Monitoring

What gets measured gets managed, and in modern manufacturing, data is the bridge between good and exceptional. Real-time monitoring allows leaders to identify bottlenecks, measure yields, and optimize throughput based on actual performance metrics.

You’re probably wondering: how does this translate to cost savings? The answer lies in small, consistent gains. Monitoring tools and dashboards can reveal trends that might go unnoticed, such as:

- Gradual tool wear is causing micro-deviations in cut quality.

- Overuse of energy or water in certain cycles.

- Recurring downtime patterns tied to specific jobs or teams.

Once identified, these insights help refine scheduling, training, and resource use. Over time, those small improvements compound, creating a culture of efficiency and accountability across the entire operation.

Final Thoughts

Precision and cost control are no longer competing priorities. With the right mix of disciplined processes, advanced cutting systems, and data-led decision-making, businesses can achieve both and stay ahead in competitive markets.

Each of these strategies may seem small on its own, but together they form a framework for operational excellence. Whether it’s tightening procedures, exploring new technologies like waterjet cutting, or leveraging automation, every step leads closer to higher quality and lower costs.